Challenge

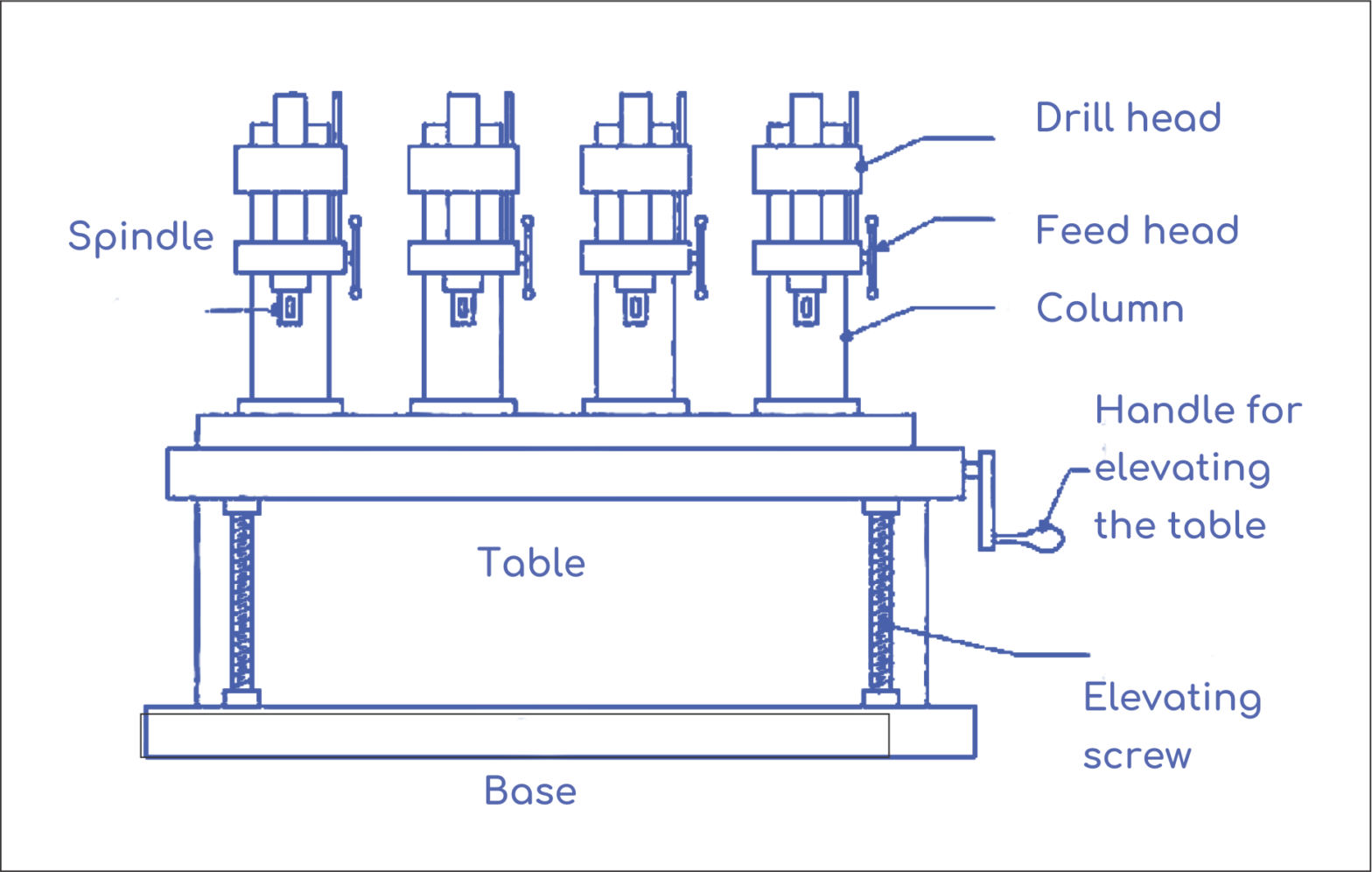

The client, a piston manufacturing company, wanted to design a special purpose machine that could produce pistons of high quality, with a combination of drilling, hole milling and reaming.

The challenge was to bring down the manufacturing cost of the product by integrating the three multiple machines (used for drilling, hole milling and reaming) into one, consistently deliver highest accuracy and increase the overall production capacity of the plant.

Our Solution

Entellus designed an automation system to achieve the accuracy. The new machine supported all three machine applications viz., drilling, hole milling and reaming.

The Outcome

The solution helped the client:

> Increased piston production by 60%

> Achieved accuracy levels of up to 3 microns – the

highest in the industry

> Eliminated manual intervention for two machines

> Optimized the time consumed at multiple phases

> Cleared 40% space on the ground floor for new

machinery.

> Facilitated faster data collection

> Saved time and power consumption